The product development process takes an inventor step-by-step from a concept to production. Every company may call the phases by different names or include slightly different deliverables in each phase, but the general process is the same. At Synectic, our process is five steps but since product development is not one size fits all, you do not have to start at the beginning to get to the end. You may need to pick and choose from various phases depending on your specific product design needs. Likewise, you could find yourself in subphases or repeating phases as you develop your product. As in any type of project management, there are risks and benefits to adding or removing parts of the process. This step-by-step guide will give you an idea of what encompasses each phase of our process, but it is up to you to decide what is best for your project goals.

Phase 0: Research

This phase technically is not included in our product development process as the responsibility to complete this phase is entirely on the inventor. However, it is still an important step, so we include it as phase 0. Besides performing market research, you will need to research patents and acquire funding. We break these down further, including ways to acquire start-up capital, in our post on the three essentials for new inventors.

This phase defines the project goals starting with a formal kick-off meeting. We review the proposal and put in place a game plan detailing how the project will proceed. In some cases, your project requires a competitive patent or product review. This review outlines what is currently available on the market and highlights the pros and cons of each feature. If your invention is a medical device, you may opt for a formal clinical feedback review, where we interview local physicians and discuss the features and benefits of your device. This feedback gathered is used to write the product development specification.

The product development specification (PDS) details the problem your device needs to solve, the user requirements, and the functional requirements. Throughout the product development process, there will be several iterations of the PDS as your design grows and evolves. However, the initial PDS provides a baseline guiding the design process forward. A lot more goes into this phase, but we can’t cover it all here. Luckily, we break it down further in our phase one review.

Phase two is all about product design, and we start by reviewing the PDS again. Why do you ask? Simple, the product specification guides the entire scope of the project. If you don’t have a clear idea of what problem your product needs to solve, you would be wasting your time developing concepts that do not fit the requirements.

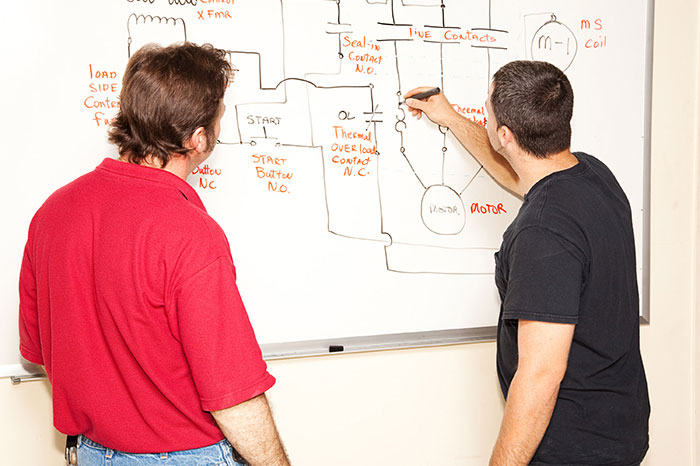

After reviewing the specifications, we have a group brainstorming session to generate concepts that meet the requirements. These concepts start as rough sketches or storyboards. We pick the best ones and then make 3D CAD models. We may also need to make simple breadboard prototypes to test proof of concept before investing the time into making CAD models. Proof of concept prototypes allow us to test the idea in real-world conditions, preventing us from going down a rabbit hole when the idea would never work.

Once we have our 3D models, we rank them using our proprietary concept matrix that weighs and grades each concept based on specific criteria. This ranking is subjective but helps narrow down which concepts theoretically work the best. Generally, the client selects one to two concepts to move into phase three.

With the concept path selected, prototype development begins. The 3D CAD models, made in phase two, are refined for ergonomics and form using industrial design techniques. Then they are made into physical parts using various prototyping methods, depending on part complexity, usage environment, material cost, finish requirements, etc. The prototypes are tested and debugged until our engineers produce a working model. Then the prototypes are tested again, this time against the PDS, to check that they meet the required specifications.

Prototype development is iterative. Meaning each prototype you make is better than the last. It also means that the process is not linear. You will have setbacks despite how knowledgeable and experienced your engineering team is. Knowledge and experience do keep setbacks minimal and corrective actions quick, however.

Throughout phase three, your design moves through several stages of design refinement, testing, and risk assessment before settling on a final prototype. In the end, you should have a de-risked design, working prototype, and preliminary quality and regulatory documentation. The final step involves freezing the design before heading into the next phase, as any major changes from this point forward will be very costly.

New product introduction (NPI) is all about refinement and testing, but unlike previous phases, it does not involve the design but the process of manufacturing your product. Most of this phase takes place behind the scenes and involves a lot of paperwork. At Synectic, we break NPI into three parts: DFM/DFA, pilot production, and pilot manufacturing. Below is a summary of phase four and new product introduction. We outline it in more detail in our “How to Launch Your Product” white paper.

DFM/DFA stands for design for manufacturing and design for assembly, respectfully. During DFM/DFA each part is redesigned for optimal fabrication and cost. Then the parts undergo a tolerance analysis which identifies variances within the manufacturing process that may affect the fit and function of the finished product. We also choose final materials and vendors, write work instructions detailing assembly, and create detailed toleranced drawings necessary for part production.

Pilot manufacturing is a test of the manufacturing and assembly process and involves the very first production builds. Pilot manufacturing also includes tooling, nest, fixture, and packaging design and testing. If your product is a medical device, here is where we will complete verification and validation along with the other necessary regulatory documentation. Regardless of the product, by the end of pilot manufacturing, you will have a developed and refined quality plan and manufacturing risk analysis.

Pilot production

Pilot production is the final step of phase four. It tests your assembly and manufacturing process against real-world scenarios to ensure it produces a safe working product. Additionally, several qualification lots are built from multiple production lots confirming that the manufacturing process has been adequately stressed and tested.

Contract manufacturing is the final step in our product development process. Unlike the other phases with a set endpoint, this phase is ongoing as we scale up production. Production runs can include a couple thousand for low-volume manufacturing to millions of units for high-volume manufacturing. The goal, at this stage, is to maintain quality, efficiency, and overhead costs.

You could try navigating the product development process by yourself, but we do not recommend it. Once you get into the later phases, design and development become complex and difficult to navigate. There is also a large amount of paperwork for quality and regulatory bodies that you need to draft and maintain throughout the project. Additionally, scaling up for manufacturing involves a lot of intricate behind-the-scenes design, development, and testing involved. Add in the possibility of do-loops, redesigns, and specification changes, and you could find yourself out of money and time if you try taking on the entire project yourself. Finding a good product development company with proven experience and dedicated project managers, who can lead you in the right direction, is well worth the expense. Synectic has over forty years of designing, developing, and manufacturing high-quality products. See what we have to offer.

Need Product Development Help?

About Synectic Product Development: Synectic Product Development is an ISO 13485 certified, full-scale product development company. Vertically integrated within the Mack Group, our capabilities allow us to take your design from concept to production. With over 40 years of experience in design, development, and manufacturing, we strive for ingenuity, cost-effectiveness, and aesthetics in our designs. Learn more about our product strategy services and see how we can help your next project.