WE TAKE A TEAM APPROACH TO CONTACT MANUFACTURING

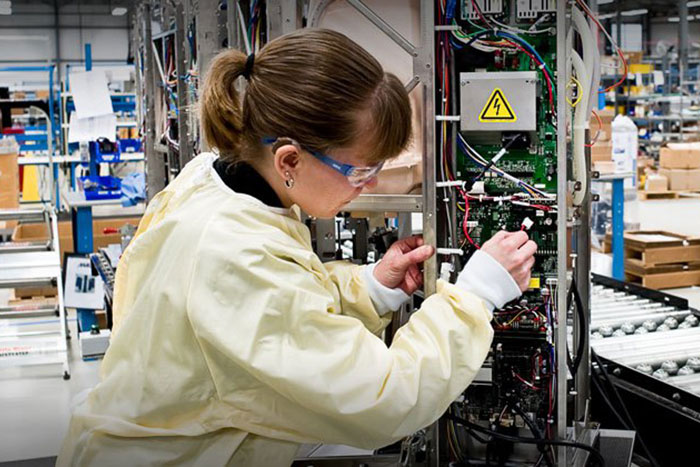

Contract manufacturing with the Mack Group means you have access to many capabilities to get your product to market. What began as simple mechanical sub-assemblies over a hundred years ago has grown into complete systems assembly, build-to-order, and order fulfillment.

The benefit of our vertical integration of services is that you can pick and choose those that fulfill your particular contract manufacturing goals. You may want a full partnership, where you can take advantage of all we offer, or you may want to take a more a la carte approach.

Build units quickly with our expanded contract manufacturing capabilities. A variety of resources are available for working with both plastic and metal parts, such as:

- Custom plastic injection molding processes such as gas-assist injection molding and structural foam molding allow flexibility in design.

- Metal parts can be cut to size using CNC machining or sheet metal fabrication.

- Inventory and supply chain management services are also available to help give your product the final push to market.

From low-volume production to high-volume manufacturing, we can meet all your contract manufacturing needs.

FULL SCALE CONTRACT MANUFACTURING SERVICES

Part Fabrication

Injection Molding

Finishing & Painting

Sheet Metal Fabrication

Assembly

Packaging Assembly

Sub-Assembled Parts

Controlled Manufacturing Environment

Manufacturing Support

Order Fulfillment

Inventory Tracking

Supply Chain Management

Manufacturing Support

Order Fulfillment

Inventory Tracking

Supply Chain Management