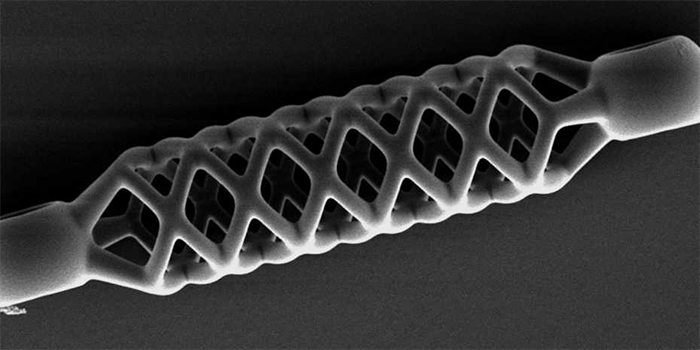

Researchers at ETH Zurich, in Switzerland, have developed the world’s smallest stent using 4D printing. The stent is 40 times smaller than the current stents available. The hope is that the stents could be used in infants and even fetuses still in the womb.

Credit: ETH Zurich

“The shape-memory polymer is suitable for treating urethral strictures. When compressed, the stent can be pushed through the affected area. Then, once in place, it returns to its original shape and widens the constricted area of the urinary tract,” says pediatric surgeon Gaston De Bernardis.

From the ETH Zurich article: “‘We’ve printed the world’s smallest stent with features that are 40 times smaller than any produced to date,’ says Carmela De Marco, lead author of the study, and Marie Skłodowska-Curie fellow in Bradley Nelson’s research group. The group calls the method they’ve developed indirect 4D printing. They use heat from a laser beam to cut a three-dimensional template – a 3D negative – into a micro mold layer that can be dissolved with a solvent. Next, they fill the negative with a shape-memory polymer and set the structure using UV light. In the final step, they dissolve the template in a solvent bath and the three-dimensional stent is finished.

It’s the stent’s shape-memory properties that give it its fourth dimension. Even if the material is deformed, it remembers its original shape and returns to this shape when warm.”

Read more about the world’s smallest stent at ETH Zurich.

About Synectic Product Development: Synectic Product Development is a full-scale product development company. Vertically integrated within the Mack Group, our capabilities allow us to take your design from concept all the way to full-scale production. We strive for ingenuity, cost-effectiveness, and aesthetics in our designs.