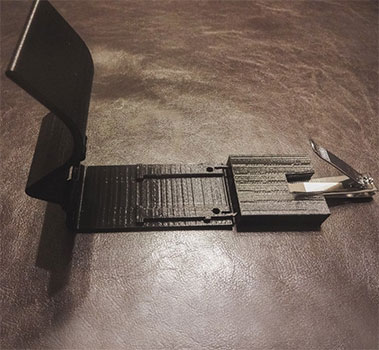

A group of engineering students at Michigan Tech has designed arthritis adaptive aids that are able to be produced using a 3D printer. This allows a low-cost alternative for arthritis patients, most of whom are elderly, bringing the overall cost of most of the products down to pennies. Additionally, because they are 3D printed they are able to be fully customizable for the user.

Credit: Michigan Tech

“This is the difference between needing to go to someone to get your nails cut and being able to do your own, which, yes, there’s cost savings, but it’s also personal pride and being able to take care of yourself,” said Joshua Pearce, the Richard Witte Endowed Professor of Materials Science and Engineering at Michigan Tech. “And if your only problem is that the standard nail clipper is too tiny, we can fix that.”

From the Michigan Tech article: “Now, Pearce is a co-author and corresponding researcher on a new study that analyzes how 20 of the 3-D printed adaptive aids his class printed see huge cost savings and either meet — or improve — standards for existing products. The study was published this week in Geriatrics (DOI: 10.3390/geriatrics3040089) and is co-authored by student research assistant Nicole Gallup and orthopedic surgeon Jennifer Bow, who is also a visiting scholar at Michigan Tech.

Pearce sees nursing homes, doctor’s offices and physical therapy clinics as the ideal hubs for 3-D printed adaptive aids. Local maker spaces and libraries also provide access to printers, designs, and knowledgeable people in exchange for fees that cover plastic and printing costs; some businesses even make a living providing 3-D prints.

With that dream in mind, Pearce says his class started with base functionality. Their assignment — turned around in a week— was printed on Rep-Rap printers that the students built themselves in the first two weeks of class. They did all their adaptive aid prints with PLA plastic, focused on handheld items, and many of the students designed features with a loved one, friend, or acquaintance in mind. They all work, but there’s always room for improvement.”

Read more about the low-cost, 3D-printed arthritis adaptive aids at Michigan Tech.

About Synectic Product Development: Synectic Product Development is a full-scale product development company. Vertically integrated within the Mack Group, our capabilities allow us to take your design from concept all the way to full-scale production. With over 40 years of experience in design, development, and manufacturing, we strive for ingenuity, cost-effectiveness, and aesthetics in our designs.