WOODBRIDGE, Conn. (September 28, 2023) – Synectic Product Development, a leader in advanced product development solutions, is excited to announce two significant developments that will propel its 3D printing capabilities to new heights. The company acquired the Formlabs 3BL Stereolithography (SLA) printer and upgraded its current Fused Deposition Modeling infrastructure to the Stratasys F170 FDM printer. These strategic moves underscore Synectic Product Development’s commitment to delivering the highest quality and most innovative prototyping solutions to its valued clients.

Formlabs 3BL SLA Printer:

The Formlabs 3BL SLA printer is highly regarded for its precision and reliability, producing intricate, high-resolution 3D prints. This advanced SLA printer is ideal for creating complex prototypes and end-use parts. With a spacious build platform, fast print speed, and a wide range of materials, the 3BL is perfect for rapid prototyping and low-volume production. It can also print large medical devices using biocompatible and sterilizable materials, ensuring that Synectic can deliver parts that meet the most demanding industry standards.

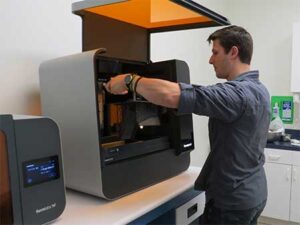

Stratasys F170 FDM Printer:

The Stratasys F170 FDM printer is widely known for its fast FDM printing capabilities, making it one of the quickest printers available. This printer is popular for its versatility and reliability, which allows it to print complex geometries in various materials. With this upgrade, Synectic can now produce parts, jigs, and fixtures more efficiently and quickly, enabling us to bring your product to the market faster.

“Both 3D printers will allow us to provide customers quicker design decisions due to having higher resolution parts printed and tested quickly in house. ” said Synectic’s President, Adam Lehman. “The new printers will also allow the SYNECTIC engineering team a wider array of materials to print parts from and the capability to print and pour urethane molds in house.”

The acquisition of the Formlabs 3BL SLA printer and the upgrade to the Stratasys F170 from the company’s previous 3D printer represent significant advancements in Synectic’s prototyping capabilities. These investments will result in faster turnaround times, enhanced product quality, and decreased overall costs for their customers.

“Having the capability to print biocompatible materials in the Formlabs BDL printer will let the engineering team print and test accurate materials that more closely simulate real injection molded parts.”

About Synectic Product Development: Synectic Product Development is an ISO 13485 certified, full-scale product development company. Vertically integrated within the Mack Group, our capabilities allow us to take your design from concept to production. With over 40 years of experience in design, development, and manufacturing, we strive for design ingenuity, cost-effectiveness, and aesthetics.