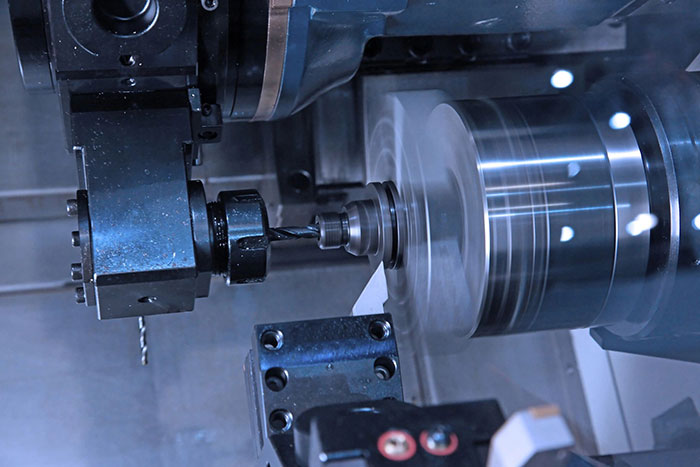

Machining, also known as subtractive manufacturing, is a process used in prototype development and manufacturing that creates the desired shape by removing unwanted material from a larger piece of material.

What are the different types of machining?

Various prototype machining techniques have been around for decades, but most fall into three principal processes:

Turning

Drilling

Milling

How does machining work?

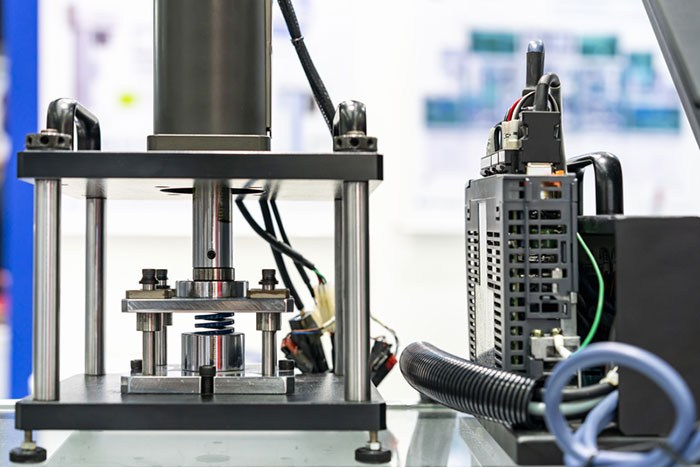

In modern product development, machining requires using a Computer Numeric Control or CNC machine. A CNC machine uses computer software to take CAD design models and map out toolpaths, turning the designs into 3D machined parts. It can create parts from a variety of materials, in varying finishes, with tolerances to the nearest .001”. Unlike rapid prototyping, machined parts use real materials reflecting the end product’s density, finish, and porosity. Machined parts are used for representative testing, models including sliding components where friction is a factor, and sealed components requiring 0 rings and gasketed surfaces.

What are some advantages of machining?

- Choice of a variety of finishes and materials

- Tighter tolerances down to .001″

- Real materials that have real densities

What are some disadvantages of machining?

- Only works from one side at a time. The object needs to be turned and repositioned manually

- Requires a skilled machinist

- Materials and time to machine can be expensive

What is an example of machining?

Synectic has extensive machining experience developing prototypes and manufactured products using our in-house CNC machine. If you are not sure if machining is the best method for your project or need help developing your prototypes, contact us below and we would be happy to help.

Need Machining?

About Synectic Product Development: Synectic Product Development is an ISO 13485 certified, full-scale product development company. Vertically integrated within the Mack Group, our capabilities allow us to take your design from concept to production. With over 40 years of experience in design, prototyping, and manufacturing, we strive for ingenuity, cost-effectiveness, and aesthetics in our designs. Learn more about our prototype development services and see how we can help your next project.