The challenge

Printed Circuit Boards (PCB), are used to mechanically support and electrically connect electronic components in an organized way. They contain traces, or tracks, of copper sheets that are etched providing “wires” from one component to another. Holes are drilled to mount components, such as resistors and integrated circuits, through the board, or they can simply be soldered to these copper traces using surface mount technology. PCBs are used in almost every electronic device from cars to simple kitchen appliances. Traditionally, custom boards can take several weeks to design, print, and ship. Synectic was approached by a startup company that needed a working prototype for testing in less than a week and at a low cost.

Synectic's solution

Custom PCBs can easily be obtained at a low cost overseas, but the shipping time was more than the week required by the customer. Domestically produced boards created an opposite problem where quick turnaround is available, but costs are very high. Synectic overcame both problems by creating custom PCBs inhouse using a CO2 laser cutter to transfer the design to the PCB.

The first step of the process required acquiring blank copper PCBs. The boards were scoured to remove the oxide layer on the copper surface. This step is necessary to produce a clean product at the end.

Next, the PCB was wiped down and sprayed with black spray paint. This is the protective mask that will be selectively removed by the laser cutter. To make sure that only the black spray paint was removed and the copper on the board was exposed, the laser cutter was programmed to cut out the negative of the traces.

Next, the PCB was wiped down and sprayed with black spray paint. This is the protective mask that will be selectively removed by the laser cutter. To make sure that only the black spray paint was removed and the copper on the board was exposed, the laser cutter was programmed to cut out the negative of the traces.

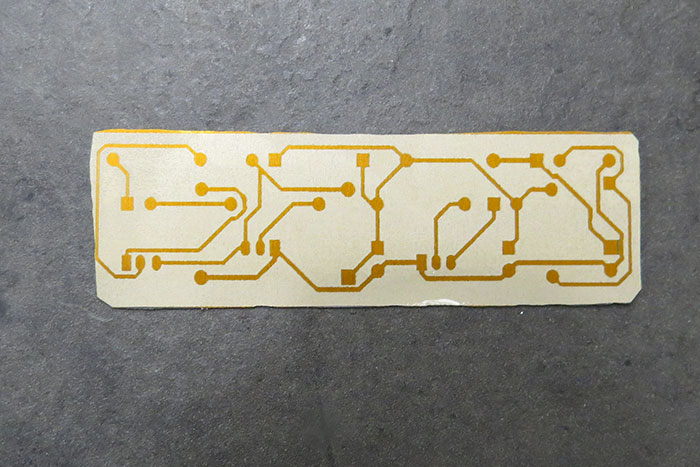

The final steps involved removing the copper. To do this, the PCB was coated in etching solution, which uses a strong acid to remove the copper where it was exposed by the laser. After a few minutes in the etching solution, the copper was visibly gone. To finish, the PCB was wiped with acetone to clean off the spray paint masking and holes were drilled for through-hole components.

The final steps involved removing the copper. To do this, the PCB was coated in etching solution, which uses a strong acid to remove the copper where it was exposed by the laser. After a few minutes in the etching solution, the copper was visibly gone. To finish, the PCB was wiped with acetone to clean off the spray paint masking and holes were drilled for through-hole components.

The result

A custom-made prototype PCB, with a turn-around time of one day, within the customer’s required budget.

Need a Custom Prototype?

About Synectic Product Development: Synectic Product Development is an ISO 13485 certified, full-scale product development company. Vertically integrated within the Mack Group, our capabilities allow us to take your design from concept all the way to production. With over 40 years of experience in design, prototyping, and manufacturing, we strive for ingenuity, cost-effectiveness, and aesthetics in our designs. Learn more about our prototype development services and see how we can help your next project.