TACKLE RISK WITH ITERATIVE PROTOTYPE DEVELOPMENT

Prototype development allows for quick testing of concepts and is the cornerstone of design. Depending on the desired part outcome and complexity, your product may demand variations or tweaks as design and development progress.

Prototype development offers an inexpensive and efficient way to identify product design flaws, usability improvements, and proper function. Here’s what you can expect when using our prototype development service:

- Using an extensive array of prototyping methods, we fabricate parts and perform first article (FAI) inspections to ensure accuracy.

- Next, we assemble individual components into the finished prototype, verifying that it meets the intended design goal.

- Finally, our prototype developers conduct all prototype testing using an approved protocol based on the Product Development Specification.

At the end of our process, you will have several iterations of prototypes as we test and refine your design, saving you time and money before manufacturing.

COMPLETE LINEUP OF PROTOTYPE DEVELOPMENT SERVICES

Product Prototypes

Demo Units

Breadboard Models

Functional Prototypes

"Works Like, Looks Like" Models

Breadboard Models

Functional Prototypes

"Works Like, Looks Like" Models

Impress stakeholders with prototypes that look good and prove your product works. Whether you need a basic, alpha prototype using 3D printing methods or a detailed functional production-ready prototype, our prototype developers can quickly and inexpensively replicate any product design.

Prototype Fabrication

3D Printing

CNC Machining

Silicone Molding

Ceramic & Urethane Casting

CNC Machining

Silicone Molding

Ceramic & Urethane Casting

Maximize time, cost, and efficiency with our wide range of in-house prototyping services. When developing your prototypes we utilize various prototyping methods such as CNC machining, 3D printing, silicone molding, and urethane casting.

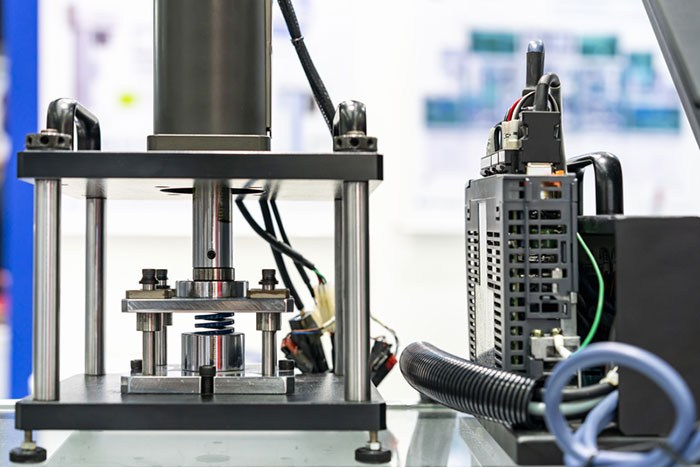

Prototype Testing

Bench Testing

Mechanical Testing

Computer Simulation

In Vivo and In Vitro Testing

Mechanical Testing

Computer Simulation

In Vivo and In Vitro Testing

Identify design flaws and improve usability with prototype testing. Our prototype developers employ various test methods such as bench testing or in vivo testing to test your prototypes against the product specification. We use the test results to refine the design before manufacturing.

Specialty Prototypes

Wire EDM

Carbon DLS

Nitinol Forming

Laser Cutting & Welding

Carbon DLS

Nitinol Forming

Laser Cutting & Welding

Tackle complex design problems with our unique array of specialty prototype solutions. Nitinol forming, Carbon DLS, Wire EDM, and laser cutting and welding are just some of the specialty prototyping solutions we are able to do in-house.