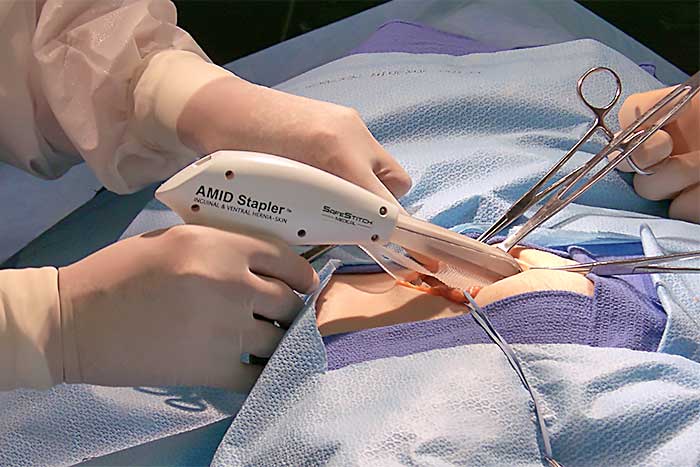

AMID HERNIA FIXATION DEVICE

A STAPLER FOR SURGICAL MESH

For decades the Lichtenstein method has been the gold standard for inguinal hernia repair. To perform this technique, a surgeon secures surgical mesh onto the abdominal wall, over the hernia, to act as a scaffold for new tissue growth. Traditionally, sutures secure the surgical mesh, but staples have become increasingly popular. Stapling pose a problem for the surgeon and the patient as traditional staplers have a straight shaft, making avoidance of the femoral artery, vein, and nerve difficult. Synectic was approached by Safestitch Medical to develop a surgical stapler that could fixate mesh during inguinal hernia repair using the Lichtenstein method. The biggest challenge was that the shaft needed to incorporate a 45° angle but still advance staples down the shaft without binding.

Synectic first developed and tested staple concepts that could correctly adhere surgical mesh to intestinal tissues. Once a staple design was selected and refined, shaft and handle development began. To combat the 45° angle staple deployment issue, we developed a separate see-through rack that fits under the shaft. The rack allowed the staples to advance in a straight line without affecting the shaft angle. It also gave surgeons a visual window for seeing how many staples they deployed. Two additional features went into the stapler’s mechanical design. The first was adding prongs onto the end of the stapler shaft to aid mesh manipulation. Second, we added feedback features to the handle and staple applier. When the surgeon squeezed the handle, it created a clicking sound, letting them know it was fully pressed. Our medical device engineers developed the staple applier in a way that the staple itself “popped” when it formed correctly. The surgeon could feel this “popping” happen. Additionally, we incorporated human factors engineering and clinician feedback for the industrial design of the handle. Finally, packaging was designed and tested for optimal sterility and ease of use.

SYNECTIC'S SOLUTION