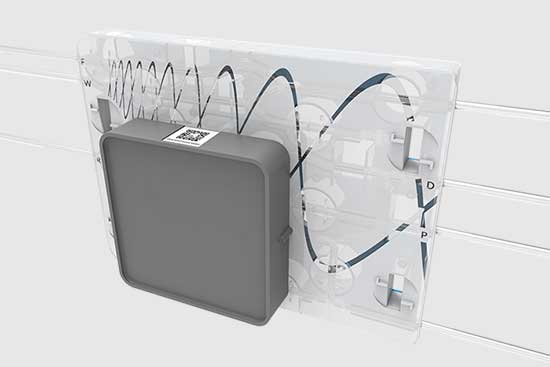

EKKO ACOUSTIC CELL PROCESSING SYSTEM

A TWO PART SYSTEM FOR USE IN GENE THERAPY

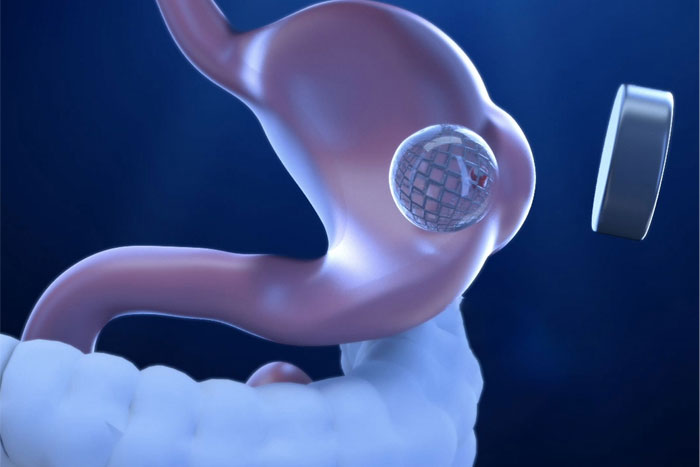

Cell and gene therapy is becoming one of the fastest-growing segments in the life sciences. The manufacturing process requires a complicated multi-step operation where high volumes of cells are separated, washed, and concentrated. One challenge for cell and gene therapy manufacturers is moving from a manual and open system to a closed and automated one. Recently a private equity-backed startup developed a novel technology for a closed and automated system that can separate solids from liquids for use in gene and cell therapies. The system creates ultrasonic waves, using gentle forces, that manipulate cells in various ways that traditional manufacturing techniques cannot accomplish. Synectic Product Development was approached to develop a piece of cell processing capital equipment that utilizes this novel technology for cell and gene therapy manufacturing. Additionally, they requested the tandem development of a single-use disposable cartridge that integrates with the capital unit. The biggest challenge was creating a working system that seamlessly integrates the capital and disposable components.

First, two teams of mechanical, electronic, and software engineers assigned to the capital and disposable projects collaborated to refine existing design concepts and CAD models. For cost reduction, we moved an expensive reusable component from the original disposable cartridge design to the new capital design. Our capital and disposable product design teams developed an intricate fluid path to address the issue of integrating the capital piece with the disposable unit. We added pinch valves into the design to control fluid flow and path. Additionally, our engineers incorporated weight and temperature systems for enhanced user feedback. Synectic’s software engineers wrote and tested firmware code on all individual sub-assemblies. Finally, we developed and tested high-level control software for optimal user experience.

SYNECTIC'S SOLUTION