MOST POPULAR WHITE PAPERS

ALL WHITE PAPERS

9 Prototype Testing Methods to Prove Your Invention Works

Prototype testing provides a cost-effective method for ensuring products meet user requirements and regulations. Simple proof of concept tests can predict future design problems and determine if further development is ... Read More

4 Brainstorming Techniques That Generate Successful Ideas

Brainstorming can be a fun exercise to solve a particular problem or expand on an idea. As an inventor, you probably already have an idea of where you would like ... Read More

Webinar: Are You Ready For Manufacturing?

No matter what your product is, the end goal is to make it to production. Make sure your product is ready by watching this free webinar. Synectic President Adam Lehman ... Read More

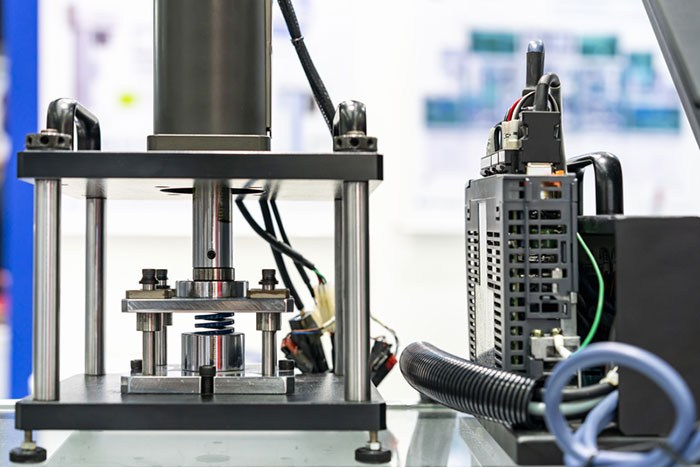

Case Study: Creating a Custom Fixture for Medical Device Assembly

The challenge Fixtures are used in product development and manufacturing for a variety of purposes. Most commonly they are used as a holding or support device, ensuring that all components ... Read More

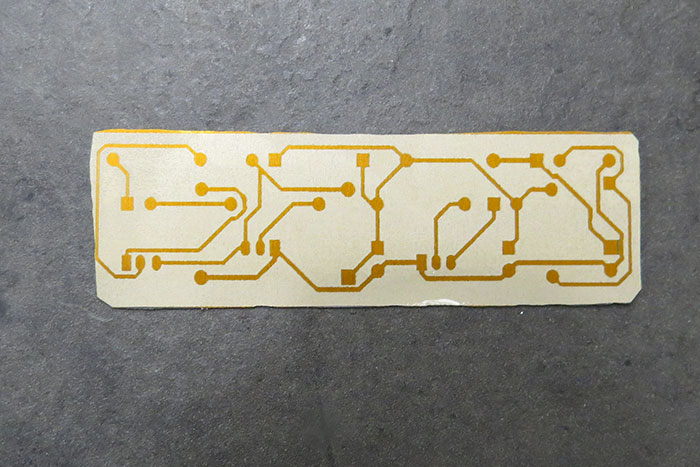

Case Study: How to Create Custom PCB Prototypes Using a Laser Cutter

The challenge Printed Circuit Boards (PCB), are used to mechanically support and electrically connect electronic components in an organized way. They contain traces, or tracks, of copper sheets that are ... Read More

How to Write a Product Design Specification (PDS)

The product specification also referred to as a product design specification, product development specification, or PDS, is a written document that describes your product and lists what you would like ... Read More

The Basics of Structural Foam Molding

Structural foam molding, like gas assist, is another manufacturing process in the plastic injection molding family. The process creates a singular large and complex part that normally requires many components to complete. In ... Read More

All About Gas Assist Injection Molding

Gas assist injection molding is a specialized technique in the plastic injection molding family. Like structural foam molding, gas assist creates an inexpensive lighter part compared to traditional injection molding. Given its versatility ... Read More