If you are asking how to launch your product, you must first ask yourself if your product is ready for manufacturing and market launch. If you respond, “Of course I am. I have a product design. I have developed a prototype. I have funding.” It would seem on the surface that you are ready for production. But, have you tested your design? Is your assembly process refined and tested? How do you know you can repeatedly produce the same product? Have you identified risks in the assembly and manufacturing process and developed a plan to mitigate them? If the answer to all of these isn’t a resounding “YES!”, you are not ready for manufacturing.

After reading the above paragraph, you may be wringing your hands with worry wondering how you will accomplish all of that. Don’t fret; this is where NPI comes in. NPI stands for new product introduction and is the product development phase between prototyping and contract manufacturing. During this phase, you refine your process and scale up production in the most time and cost-effective manner possible. If you have a regulated device, this is where you will complete the bulk of the required paperwork to meet compliance.

At Synectic, new product introduction falls under phase 4 of the product development process. Since it is a long and sometimes arduous process, we break it into the following parts: DFM/DFA, Pilot Production, and Pilot Manufacturing. These parts are broken down further into different requirements based on your individual project needs. Below we thoroughly dissect each component of the new product introduction process. For a successful product launch, you may need all the requirements or just some. The more complicated or regulated your invention, the more requirements for a successful launch

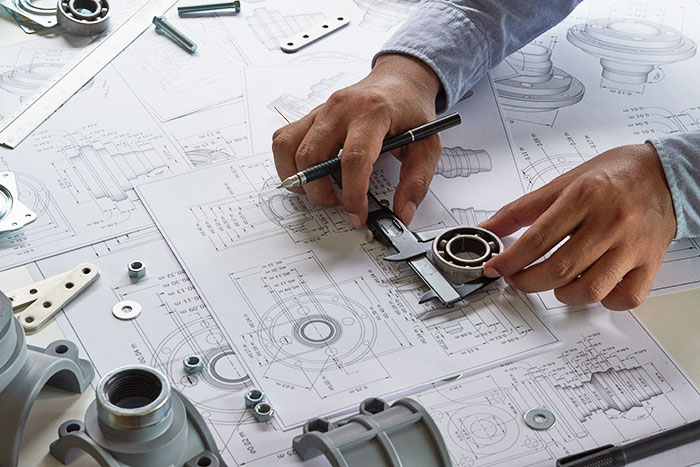

DFM/DFA stands for design for manufacturing and design for assembly, respectfully. During this part of new product introduction, specialized engineers redesign each component of your product for optimal fabrication and cost. The DFM/DFA process involves:

Critical tolerance analysis

Critical tolerance analysis is a preliminary analysis of the most critical function fits and assembly stack-ups that will contribute to reducing risk in the design. This analysis ensures that critical parts will fit together once manufactured.

Fully toleranced production drawings

Fully toleranced production drawings are detailed and contain all the dimensions, callouts, and specifications required to fabricate parts and assemblies. They account for the fabrication method, tolerances, and required dimensions.

Supplier selection

Suppliers are selected based on current ISO certifications, ability to make the parts to specification, good manufacturing practices, appropriate internal systems to support production needs, and ability to deliver parts on time.

Final materials selection

Material selection of final production materials considers strength, robustness, sterilization, biocompatibility, working conditions, fabrication method, and assembly methods.

Costed BOM

The Bill of Materials, or BOM, is a cohesive list, including necessary quantities, of all materials, components, parts, and assemblies required to produce the finished product. You can think of the BOM as the ingredient list in the “recipe” to create your product. In the case of a costed BOM, the bill of materials includes the cost of each component in the quantities necessary to provide a yearly supply of parts.

Work instructions

Work instructions outline the manufacturing assembly process. They are used to train manufacturing assembly personnel and the manufacturing team on how to assemble your product. The work instructions contain detailed steps outlining how to carry out procedures. They also include the assembly line layout and process description.

Detailed design review

After refining the design for manufacturing and assembly, it is reviewed and approved. The purpose is to suggest improvements in the final design, at a detailed level, before proceeding. This review is the last chance for design changes before it is completely frozen.

Machined pre-production prototypes are tested against protocols to see if earlier changes or design modifications affected product functionality.

This phase of the NPI process has three components: documentation, building, and testing. Building and testing tend to happen in tandem, as once a system or fixture is built, it needs testing. The test results provide feedback leading to adjustments in the process. Those adjustments will also require testing to prove they work, and so forth.

Documentation

Pilot manufacturing requires a large amount of documentation focused primarily on quality checks. More paperwork occurs during this phase than any other. The Design History File (DHF) setup at the beginning of the project store all the documentation. Every part and process needs to be cataloged and traceable. If your project is a medical device, additional documentation may be required based on what you will need to pass FDA inspection. Even if you do not have a regulated device, the documents fall within the umbrella of good manufacturing practices and are standard practices for manufacturers. Once your design freezes at the end of DFM/DFA documents are not easily changed, so accuracy and communication between parties are critical. The documentation you will complete during manufacturing includes:

Quality and manufacturing plan

A quality and manufacturing plan ensures you follow a high level of quality throughout the entire build process. It lays out which party is responsible for each build task, quality document, and procedure. It also helps smooth out any rough edges in the manufacturing process.

Quality inspection forms (QIF)

Quality Inspection Forms (QIFs), also known as receiving inspection or material inspection, validate the quality of incoming parts/components/materials. The acceptance criterion follows parameters determined when setting up the project plan. Receiving inspection is performed by quality assurance personnel to resolve quality issues during pre-production.

First article of inspection (FAI)

The First Article of Inspection (FAI) occurs on all incoming parts ensuring that the manufacturing process does not alter critical dimensions. The FAI verifies that parts produced from a tool comply with the original measurements laid out in the design drawings.

Device master record (DMR)

The Device Master Record (DMR) is a compilation of all instructions, drawings, packing specifications, labeling, and maintenance procedures for your device. The DMR separates the manufacturing process from the design process and contains everything needed to build and test your completed product. It is essentially a recipe for how to manufacture and assemble your product. A complete, well-organized DMR is critical for a medical device to pass FDA inspection.

Machinery failure mode and effect analysis (MFMEA)

MFMEA stands for Machinery Failure Mode and Effect Analysis and is a methodical approach used for identifying risks associated with machinery and equipment failure. In short, each manufacturing operation will be reviewed and assigned a risk score. If the risk score is above a specified threshold, then a fixture or test is recommended to address this risk.

Building and testing

Several unit lots are built at various points during the pilot manufacturing phase to be used in debugging both the assembly and manufacturing process. Engineers design, build, and test packaging, ensuring it can withstand normal wear and tear, shipping, handling, and, in the case of medical devices, sterilization and biocompatibility. Development and testing of assembly and manufacturing processes also happen during pilot manufacturing, proving the build is accurately repeatable. The units produced during this process are not sellable but instead used as demo units in the field. Here is what is designed, built, and tested during pilot manufacturing:

Tooling is the process of designing and developing tools that are needed to manufacture the parts and components of your product. Tools refer to various manufacturing aids, including dies, fixtures, and molds. Each part requires a specific tool design. Since tools are complicated to design and create, lead time and cost are high.

Fixture and nest design

Fixtures and nests are used in the manufacturing process to ensure uniformity of assembly. Depending on the assembly process, producing the finished product may require several different nests and fixtures. Fixtures and nests are designed and developed individually for your specific product. At Synectic, when designing nests and fixtures we optimize for efficiency, cost-reduction, and longevity.

Assembly process development

We conduct a series of tests to develop the assembly process for building each subassembly. Based on previously agreed upon performance specifications, we establish optimal operating parameters as well as a process window. The process window is the acceptable test value required to consider each part correctly assembled. In a nutshell, these tests ensure that the assembly process works.

R&D build and testing

The R&D build offers a lower-cost solution to identifying and remedying risks early. Here is when you want to make changes to the work instructions before they come under document control later in the process. Once the R&D build is complete, we test the product against the same procedures used in full-scale production. These R&D units are fully functional and often used as demo units.

Unlike the R&D build, the verification and validation build is done under fully documented quality control using our proprietary quality management system. Any changes to the work instructions at this point require a paperwork trail adding time and cost. The units produced will test verification and validation, biocompatibility, sterility, and packaging against the requirements outlined in the product development specification. The test results prove, to regulatory agencies, that the resulting product can function accordingly with minimal risk. The results also set a baseline for sterilization and packaging testing.

Packaging design and testing

Like the product itself, packaging requires design, prototyping, and testing to ensure it meets all requirements and does not damage the product inside. Packaging is subjected to various tests simulating what the product can endure during transport, such as shaking or dropping. If your packaging incorporates a tray with a peel-off lid, the lid requires peel strength and adhesion tests. For products needing an airtight seal, we test packaging for air bubbles. A real-time aging test analyzes the effects time and aging have on the product and the packaging.

Biocompatibility testing determines whether a product performs as intended without causing any adverse or harmful effects to the end-user. They also mitigate any biological risks posed by the product. Depending on your medical device class, biocompatibility testing is required in most markets to obtain regulatory approval from the FDA.

Sterility testing

Sterilization validation checks that the manufactured medical device can withstand proper sterilization processes. It also tests that the product is unchanged after the sterilization process, guaranteeing that your device is workable and safe.

Pilot production

Pilot production is the final part of the new product introduction journey before heading to full-scale contract manufacturing. The units produced in the NPI area during these pilot production builds are tested against real-world scenarios to ensure a safe working product at the end of the manufacturing process. Additionally, the process window established during pilot manufacturing expands to include the highest and lowest limits needed to produce a safe working finished product. Best of all, the units produced are traceable and sellable. Pilot production includes:

Installation qualification (IQ)

Installation qualification establishes objective evidence that all aspects of the process equipment and ancillary system installation adhere to the manufacturer’s approved specification and that the recommendations of the supplier of the equipment are suitably considered.

Operational qualification (OQ)

Operational qualification is a collection of approved protocols and tests used to verify a system is functioning properly. OQ is used to assess the performance of a system is consistent and within the parameters of the user requirement specifications.

Performance qualification (PQ)

Performance qualification is a series of test cases used to verify a system performs as expected under simulated real-world conditions. PQ is used to establish confidence through appropriate testing that the finished product or process produced by a specified process meets all release requirements for functionality and safety, and the procedures are effective and reproducible.

Qualification lots

Qualification lots are built in succession and tested against the previously approved end of line testing protocol. They use parts from multiple production lots, confirming that the manufacturing process of producing usable components is adequately stressed and the process is stable and repeatable. Qualifications lots are the final test done in the NPI area before contract manufacturing, and the units produced from these lots are traceable and sellable.

Once you have successfully completed the three parts of new product introduction, your product is fully ready for contract manufacturing. If you choose to skip this part of the process and dive into manufacturing directly after prototyping, you could find yourself backtracking at a large cost. We strongly recommend fully developing your manufacturing and assembly process with a product development company familiar with scaling up a product. If you are unsure whether you are ready for manufacturing, contact us, and we would be happy to help.

Are You Ready for Manufacturing?

Find out with our manufacturing checklist that details everything you need to begin manufacturing your product.

Download your free checklist now!

"*" indicates required fields

About Synectic Product Development: Synectic Product Development is an ISO 13485 certified, full-scale product development company. Vertically integrated within the Mack Group, our capabilities allow us to take your design from concept to production. With over 40 years of experience in design, development, and manufacturing, we strive for ingenuity, cost-effectiveness, and aesthetics in our designs. Learn more about our new product introduction services and see how we can help your next project.