Hologic Acquires Bolder Surgical

Hologic, Inc., a women’s health leader, recently acquired Bolder surgical for $160 million. Bolder surgical is a privately held medical device company producing

Hologic, Inc., a women’s health leader, recently acquired Bolder surgical for $160 million. Bolder surgical is a privately held medical device company producing

A recent article put out by Bloomberg predicts an increase in medical device sales and innovation in 2021, after the 2020 lull. With

A Connecticut medical device manufacturer will produce ventilators for the state. Governor Ned Lamont has contracted with the company for the work.

From people in their homes to small businesses to major manufacturers, there’s a huge effort to make masks to protect against the

Researchers at Yale New Haven Health System have devised a way to sterilize N95 respirator masks, which are currently in short supply

A doctor at the University of Connecticut is utilizing 3D printing technology to make life saving medical makes, similar to N-95 masks,

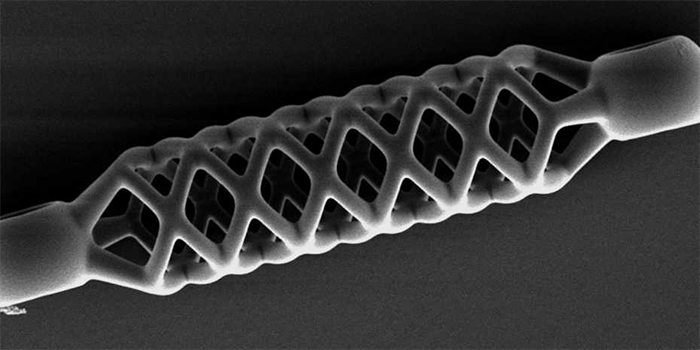

Researchers at ETH Zurich, in Switzerland, have developed the world’s smallest stent using 4D printing. The stent is 40 times smaller than

A group of students at Stevens Institute of Technology has developed a smart pediatric tracheostomy device. The device is designed to alert

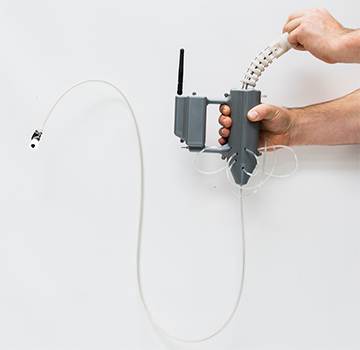

Engineers at the University of Leeds, in England, have redesigned the traditional endoscope to be more affordable for use in countries where

A team of students at Rice University is developing a small, foldable epinephrine delivery device that can be worn on the wrist,

This website uses cookies to provide you with the best user experience possible. By continuing to use our site, you agree to the terms in our privacy policy.